Business process optimisation is one of the most effective ways to improve return on investment. At its core, it is about simplifying how work gets done so organisations create more value with fewer wasted steps.

Table of Contents

ToggleWhat does business process optimisation mean?

Business process optimisation means looking closely at how the business operates and addressing the activities that drain time or money. Technology often plays a role, but the real gains come when people and culture are part of the change. The aim is stronger outcomes with the same or fewer resources.

Key benefits include:

- Less time spent on repetitive manual tasks

- Lower operating costs through reduced duplication

- Faster service and delivery for customers

- Clearer accountability across teams

How can you identify processes that need improvement?

The first step is to recognise where the business is losing time, money, or clarity. Common warning signs include:

- Staff repeating the same task in multiple systems

- Delays in approvals or decision making

- Customer complaints about errors or slow service

- Unclear ownership of certain steps

A structured way to surface these issues is process mapping. Document each stage of a workflow from start to finish. This highlights wasted effort, overlaps and bottlenecks. Involving employees in the exercise is essential because they often see problems that aren’t visible at the top level.

Which steps should you take to improve processes for ROI?

Once weak points are identified, the focus shifts to action. The aim is to connect every improvement directly to measurable business outcomes. Key steps include:

- Define goals and link them to financial outcomes, such as reduced costs or faster billing

- Map current workflows to establish a clear baseline before changes are made

- Eliminate repetitive tasks that add no value

- Apply automation to routine activities like data entry or reporting

- Monitor progress and measure results against the expected ROI

Each step ensures process changes are purposeful and accountable, rather than change for its own sake.

What does technology help with process optimisation?

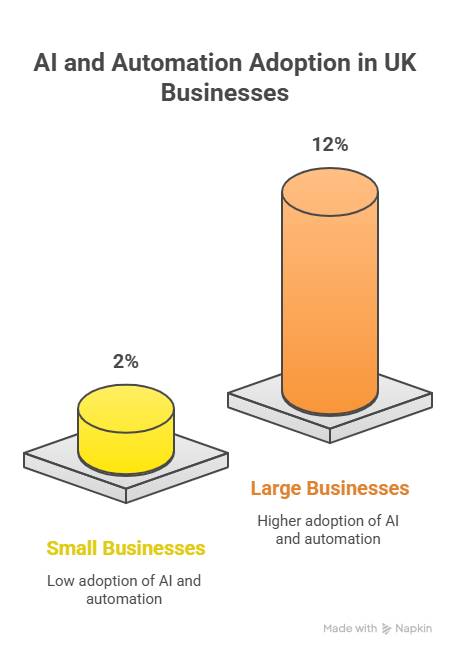

Technology is a critical enabler of process improvement. In the UK, adoption of automation and AI is growing but still uneven. The Business Data Survey 2024 found that only 2% of businesses using digitised data apply AI or automated decision making, compared with 12% of large firms. The gap shows how much potential is still untapped.

Examples of tools that support optimisation include:

- ERP systems such as SAP, which bring finance, supply chain, and operations together in one platform

- Analytics platforms that provide real-time insight into performance

- Automation tools that remove repetitive data entry and reduce human error

The technology itself is only part of the picture. The real value comes from integration. Systems must connect so information flows smoothly across departments, avoiding duplication and giving decision makers a single, reliable view of the business.

How do people and culture affect process optimisation?

Processes only work if people use them. Success depends on people understanding why changes are happening and how these changes make their work easier.

Practical steps include:

- Involving employees in the design of new processes

- Providing training so teams can use new tools with confidence

- Creating accountability by assigning clear process owners

- Recognising and rewarding improvements to maintain momentum

When employees see the benefits first hand and feel part of the change, adoption is higher and the improvements last longer.

What results can you expect from business process optimisation?

The gains show up in both financial and operational performance. Recent examples from UK organisations highlight the value:

- Automated warehouse systems have reduced operational costs by 25 to 30% and improved order accuracy.

- A major UK retailer saw a 25% increase in picking speed after deploying AR glasses in its distribution operations.

- In sectors such as retail, automotive, banking, and mining, clearer processes translate into fewer errors, lower costs, and stronger customer satisfaction.

The consistent theme is efficiency that can be measured and improvements that directly support business goals.

How should you measure the ROI of process changes?

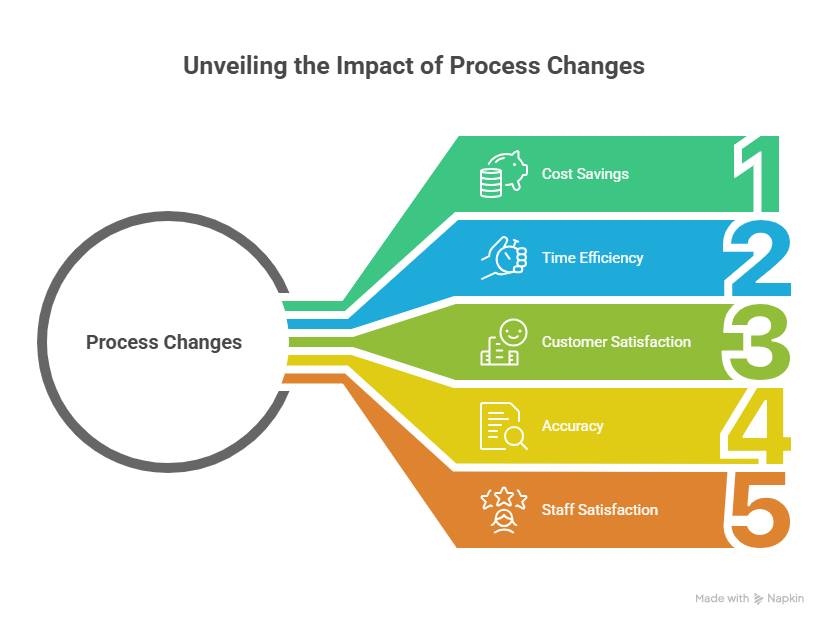

Proving success comes down to tracking measurable outcomes. Useful metrics include:

- Cost savings from reduced manual work

- Hours saved through automation

- Reduction in customer complaints or service delays

- Lower error rates in reporting or compliance

- Improved employee satisfaction scores

ROI is not static. Business environments shift, and processes must adapt with them. Regular reviews, ideally on a quarterly basis, keep improvements aligned with company goals and ensure the benefits continue over time.

Conclusion

Business process optimisation is not theory. It is a practical way to improve performance and increase ROI.

Lasting improvements come from spotting inefficiencies, taking clear steps, using technology wisely and involving people at every stage.

The UK market will keep shifting, but organisations that take control of their processes will be well positioned to grow and compete.

Also Read: IoT Security For 2025 and Beyond – Protecting a Hyperconnected World

Related posts

Hot Topics

How Skywork Helps You Brainstorm Good Podcast Names That Stand Out

Your show title is crucial for attracting potential listeners. It’s the first thing they see and can make or break…

A Complete Guide to Missed Call Solutions for Businesses

Communication is the heart of every business. Whether you are running a small shop or managing a large enterprise. Staying…